In this write up I will be providing walk through

step-by-step instructions on how to assemble or rebuild your Team Associated

diff. Below is the actual kit and also

the rebuild kit.

In my write up I will

be will be rebuilding a diff but the assembly of a fresh new diff is the same.

You will need the following items. The electric motor spray is only needed to

clean parts if you plan on rebuilding a used diff. The two types of greases will be needed to

build the diff.

First, remove the diff from the car and disassemble the kit

using an Allen wrench from one side of the diff.

Clean all used parts with the motor spray. After spraying the parts be sure to wipe

clean with paper towel. I found it

easier to spray the towel first before cleaning the balls. Roll the balls with your finger on the wet

paper towel. Careful, they are easy to

lose. There are two different sizes so

beware not to mix them up.

Now it’s time to assemble the diff.

Apply a small bead of clear grease to inside of both

outdrives as show below.

After you have applied the grease install one steel plate on

each end. Note: Be sure to line up notch

correctly on each plate as shown.

Next, install a small amount of clear grease in each hole of

the main gear and install one ball in each hole. Tip: It makes the job easier to add small

amount of grease to the end of a toothpick to pick up each ball and input into

hole.

Then add small amount of clear grease to top and bottom of

gear.

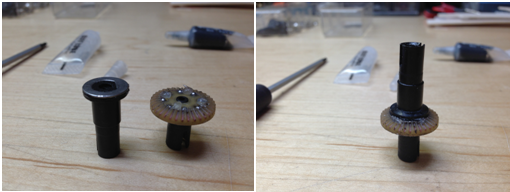

Set main gear on shorter outdrive and shown below. The applied clear grease should stick the

gear to the outdrive. Once you confirm

you have the gear on the correct drive place the longer outdrive on top as

shown.

The last part of the assembly is to assembler the thrust

balls. There are 7 of these. Be sure to use the black grease at this time.

Assemble the screw as in the picture below.

Using a bench vise or other tools may help in this next

step. Apply small amount of black grease

all the way around top washer as shown.

Using a toothpick again place each of the seven thrust balls

around the washer as shown. Once all seven balls have been set correctly place

the last small washer on top.

Last step is using the Allen wrench, carefully insert

assembled screw into long end of outdrive as shown.

Use something flat to hold other end while you tighten down

the diff. Once the screw is tight stop

tightening and back out about a half of a turn.

DO NOT OVER TIGHTEN.